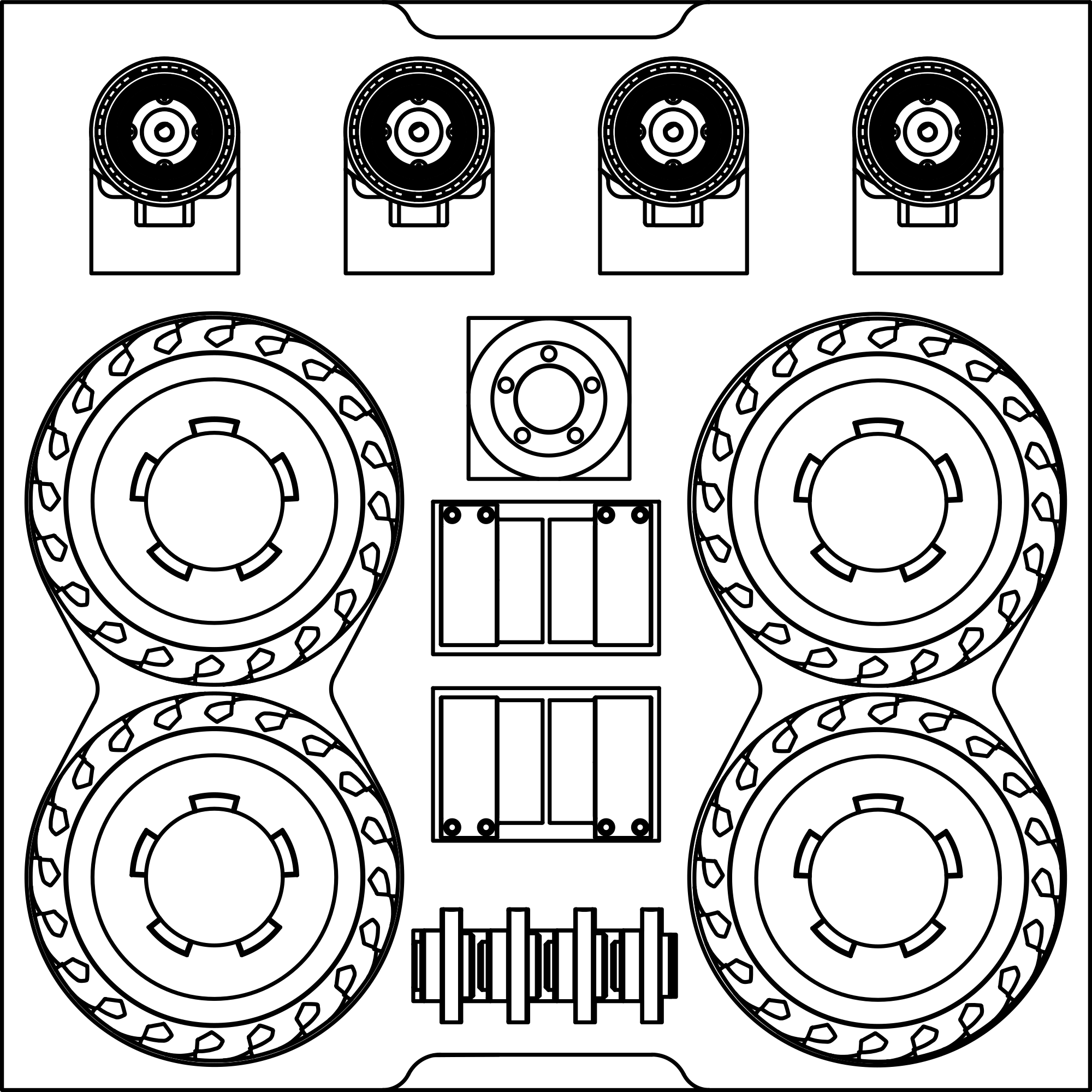

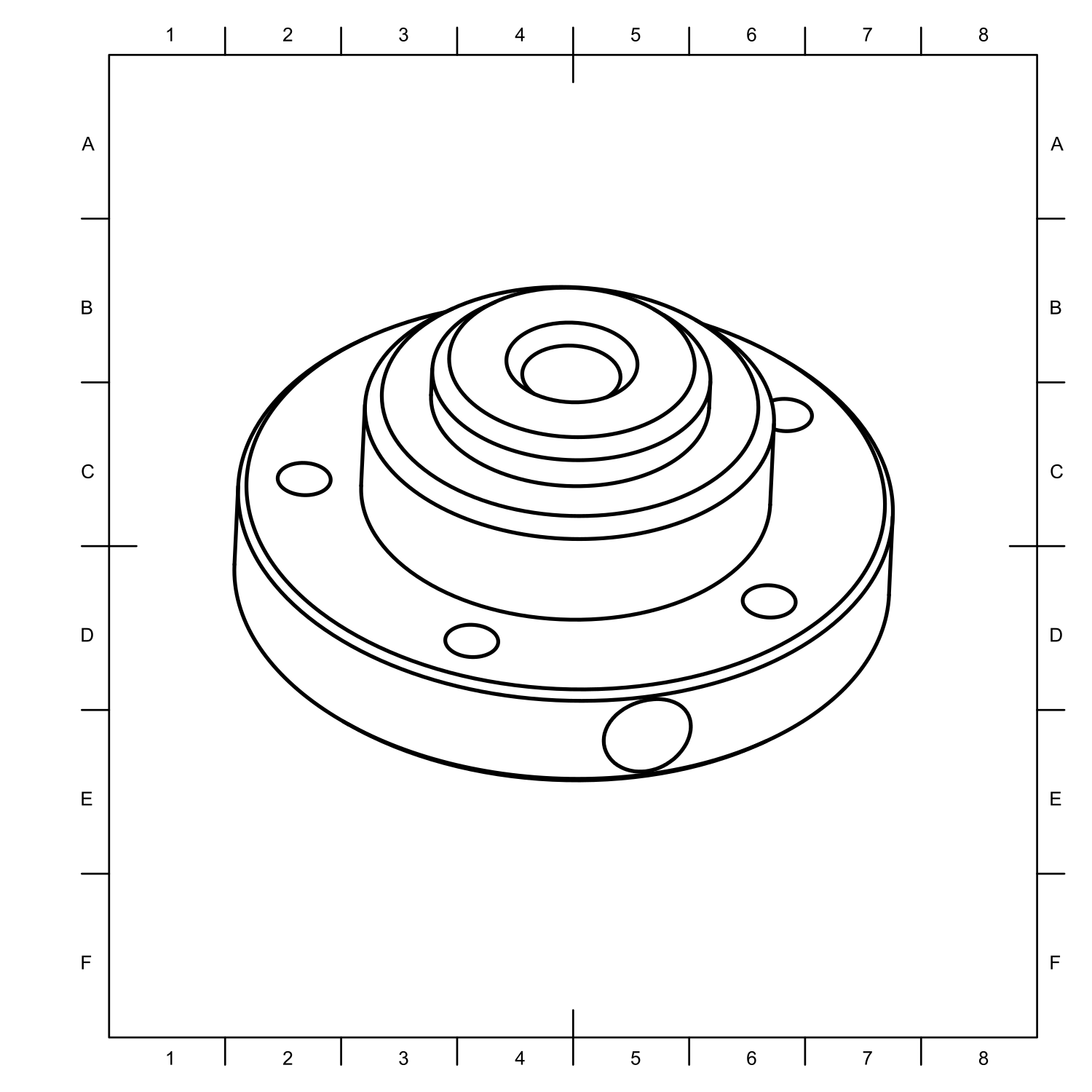

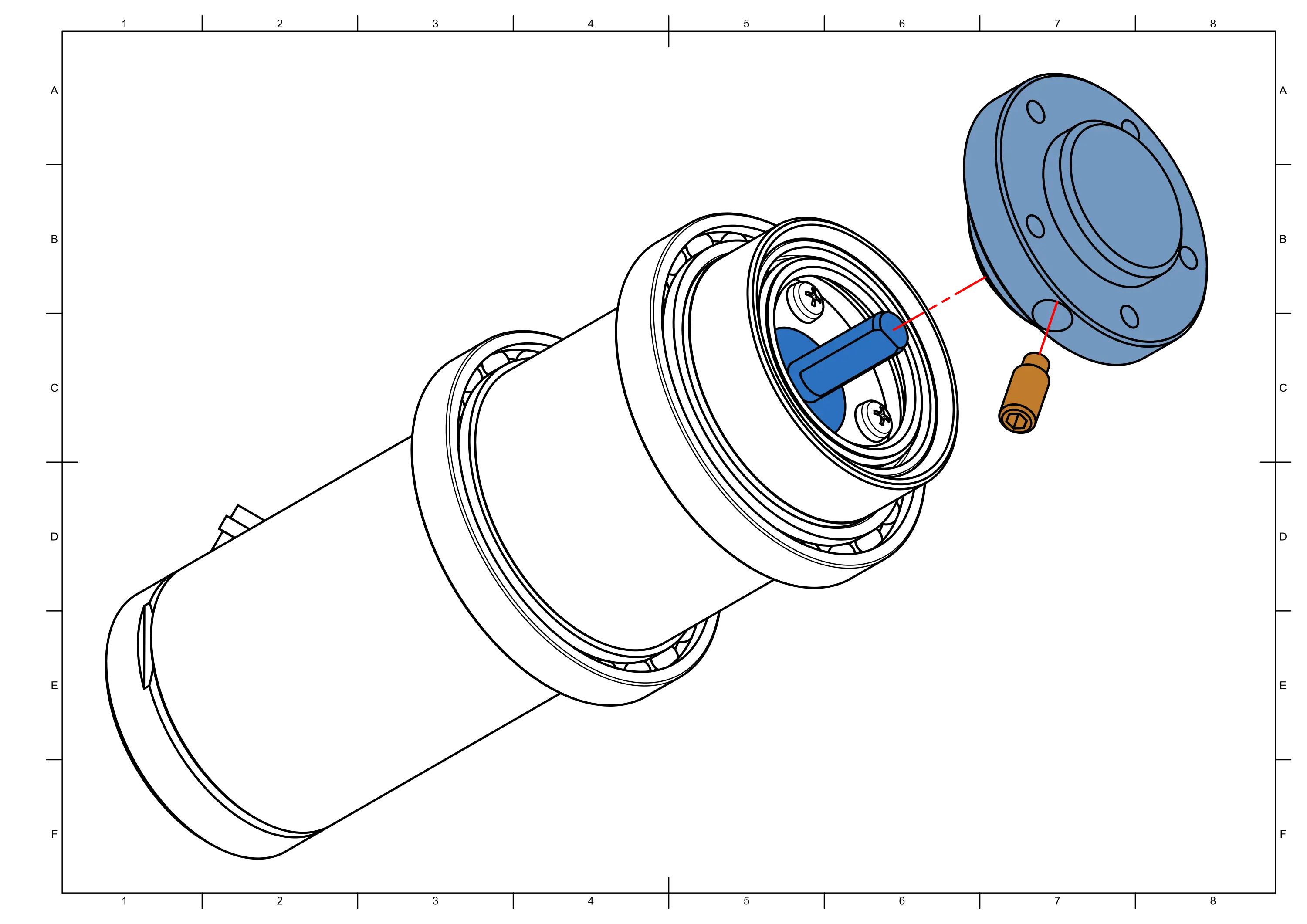

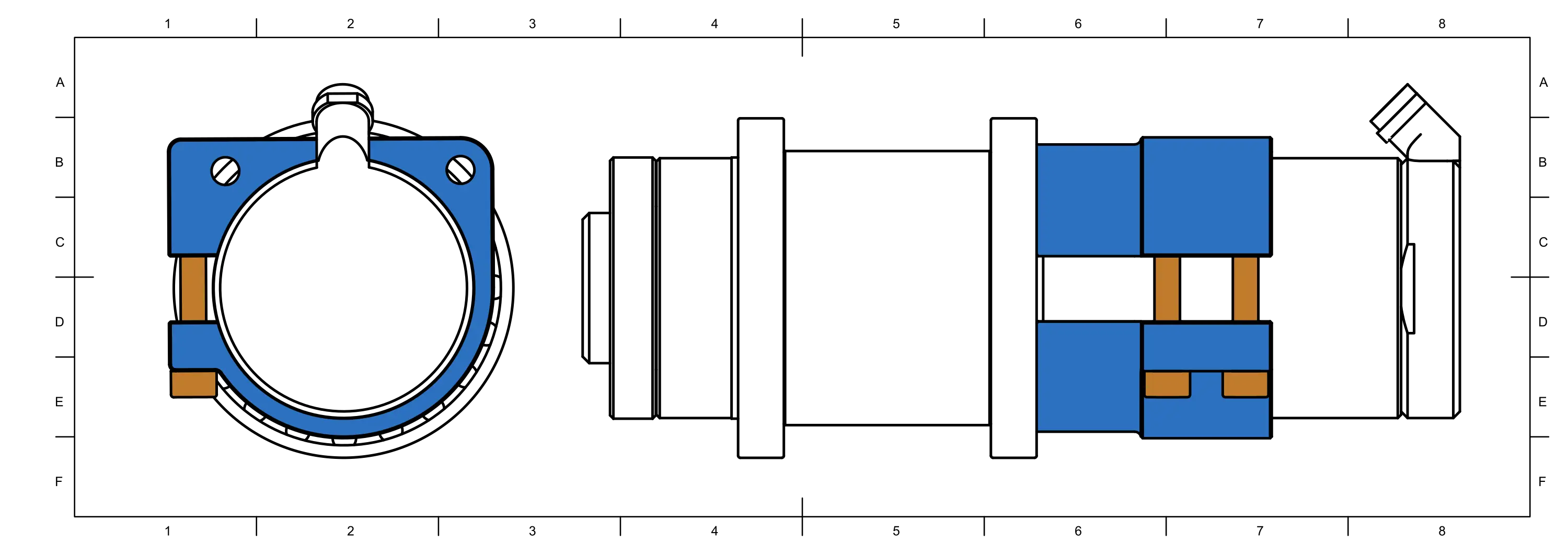

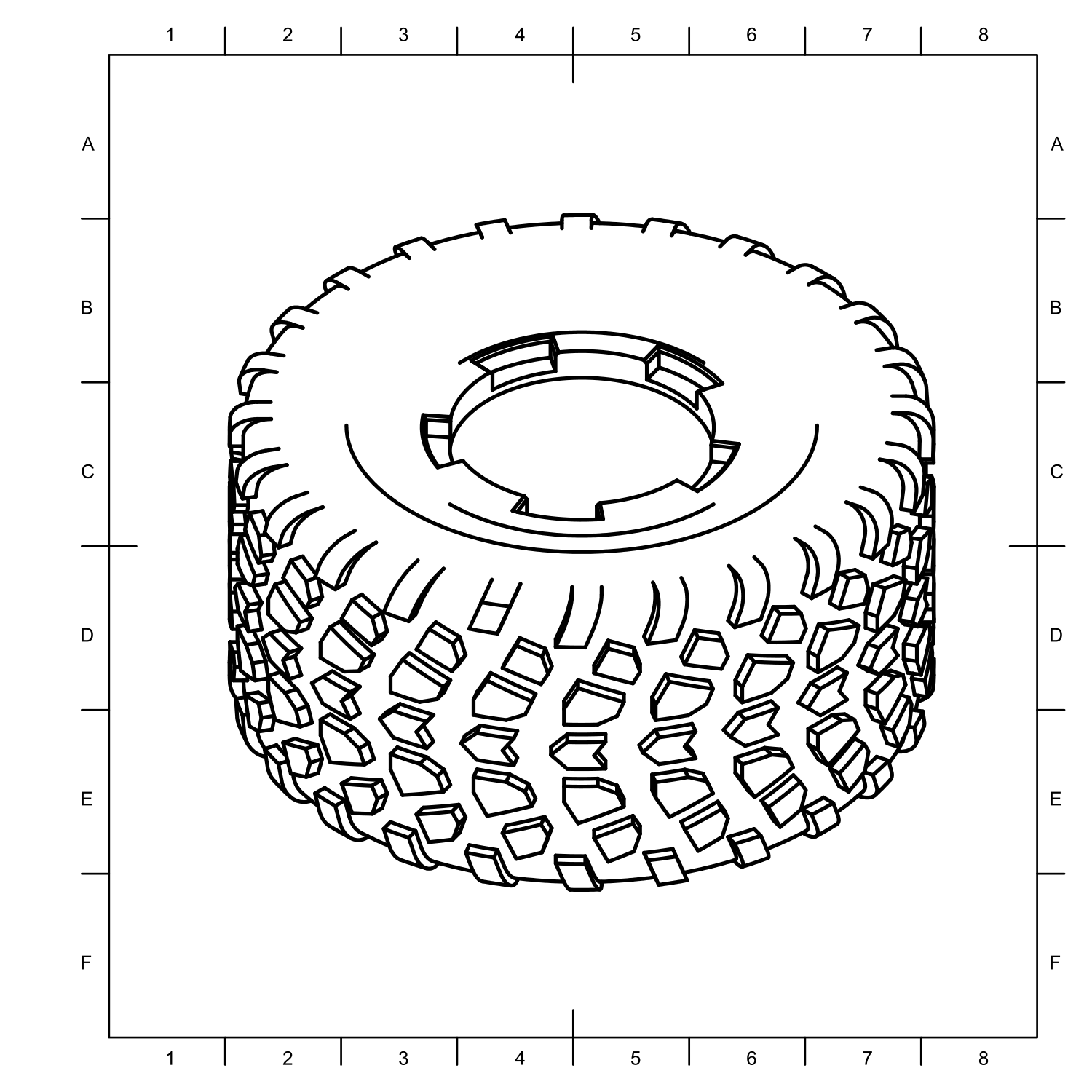

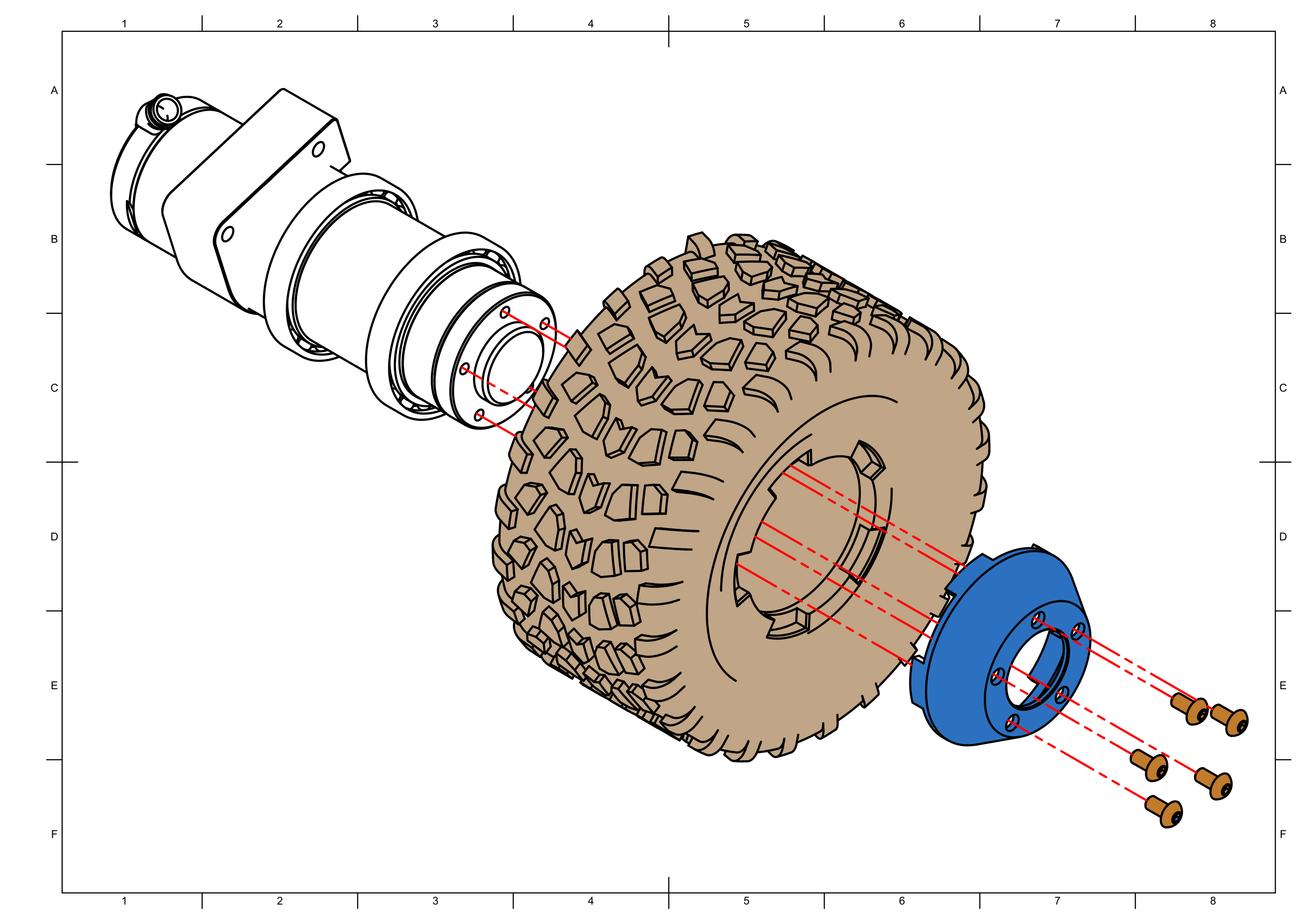

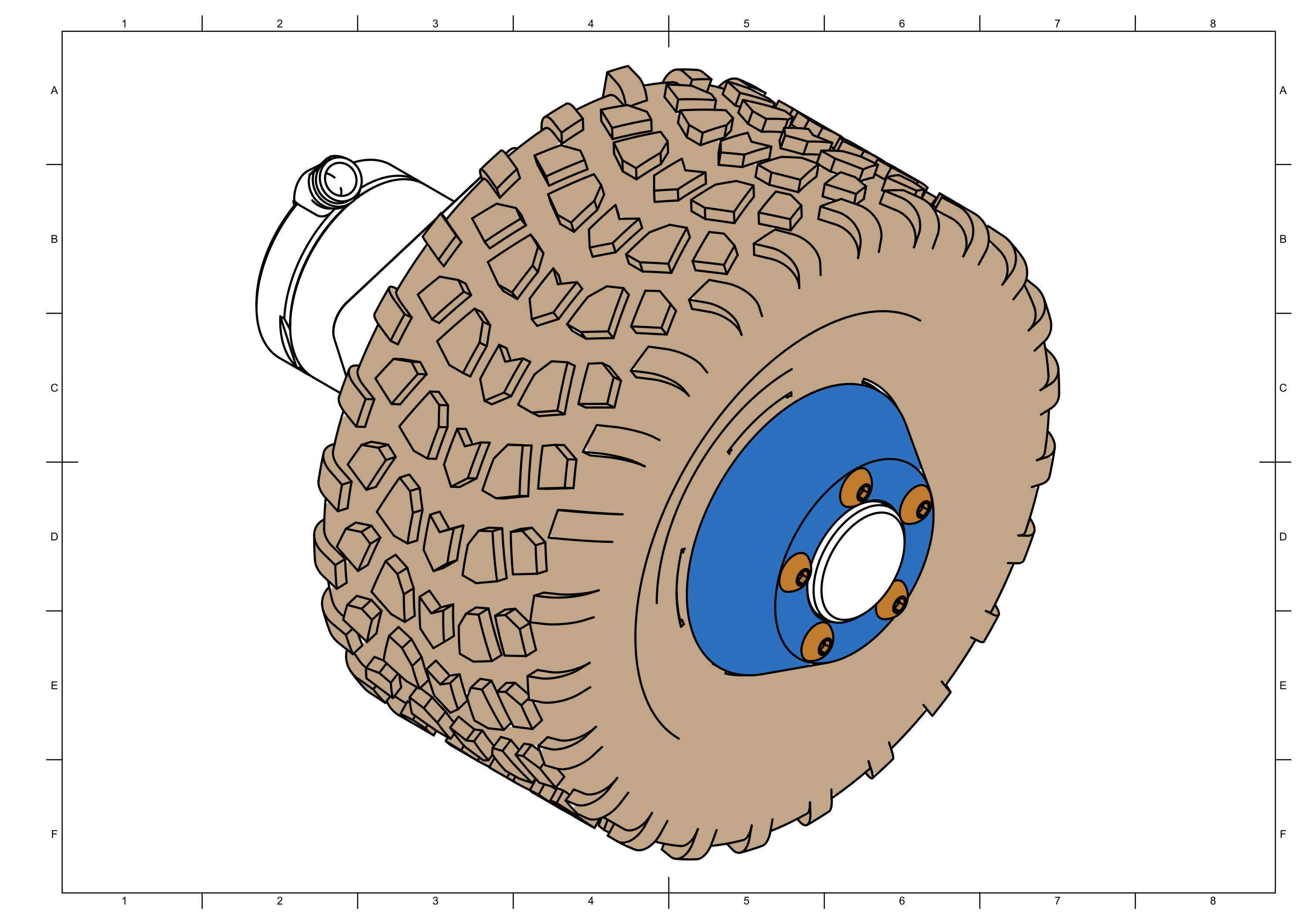

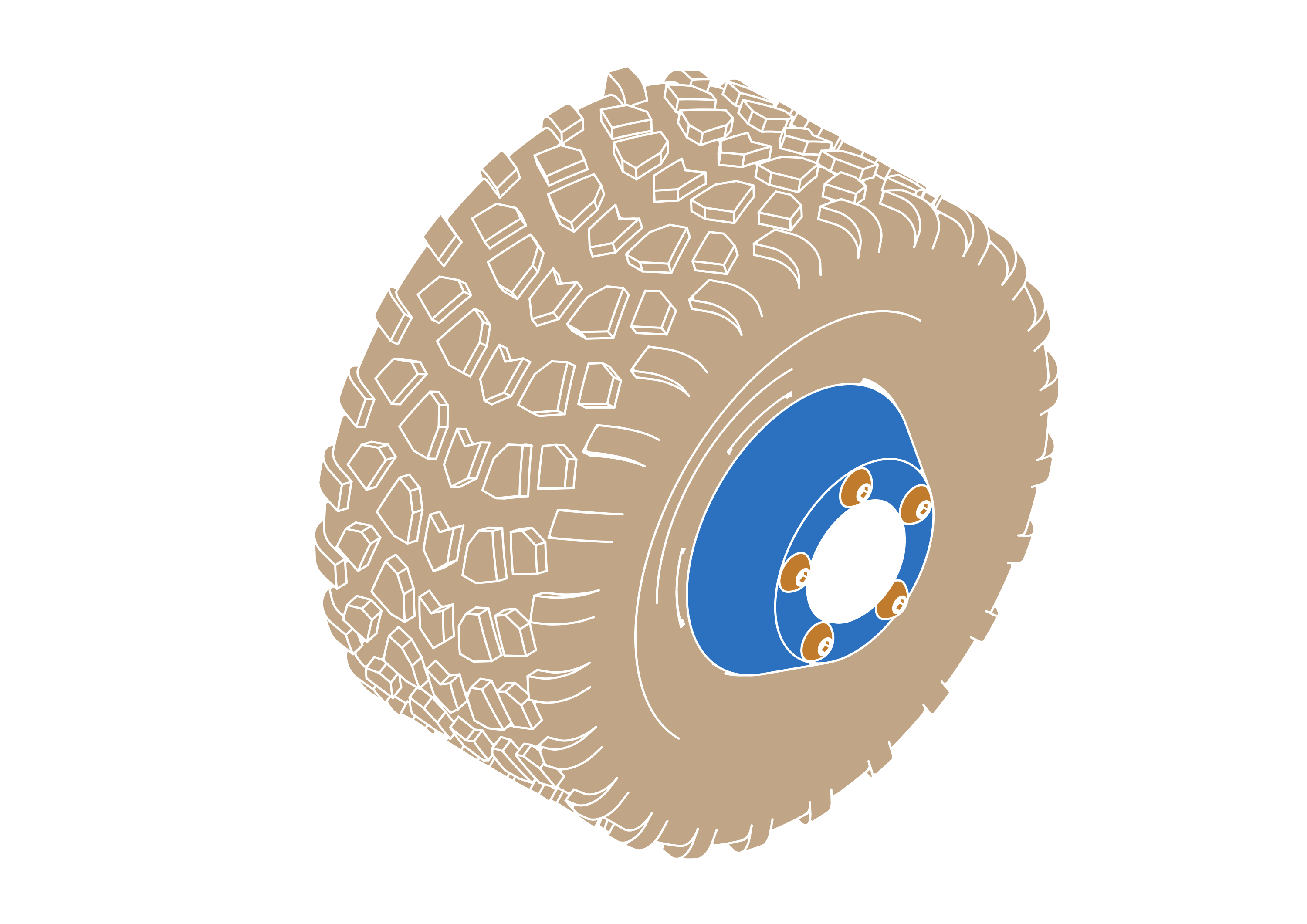

Task 1: Wheel Assembly

Assembly time ≈ 15 minutes per wheel

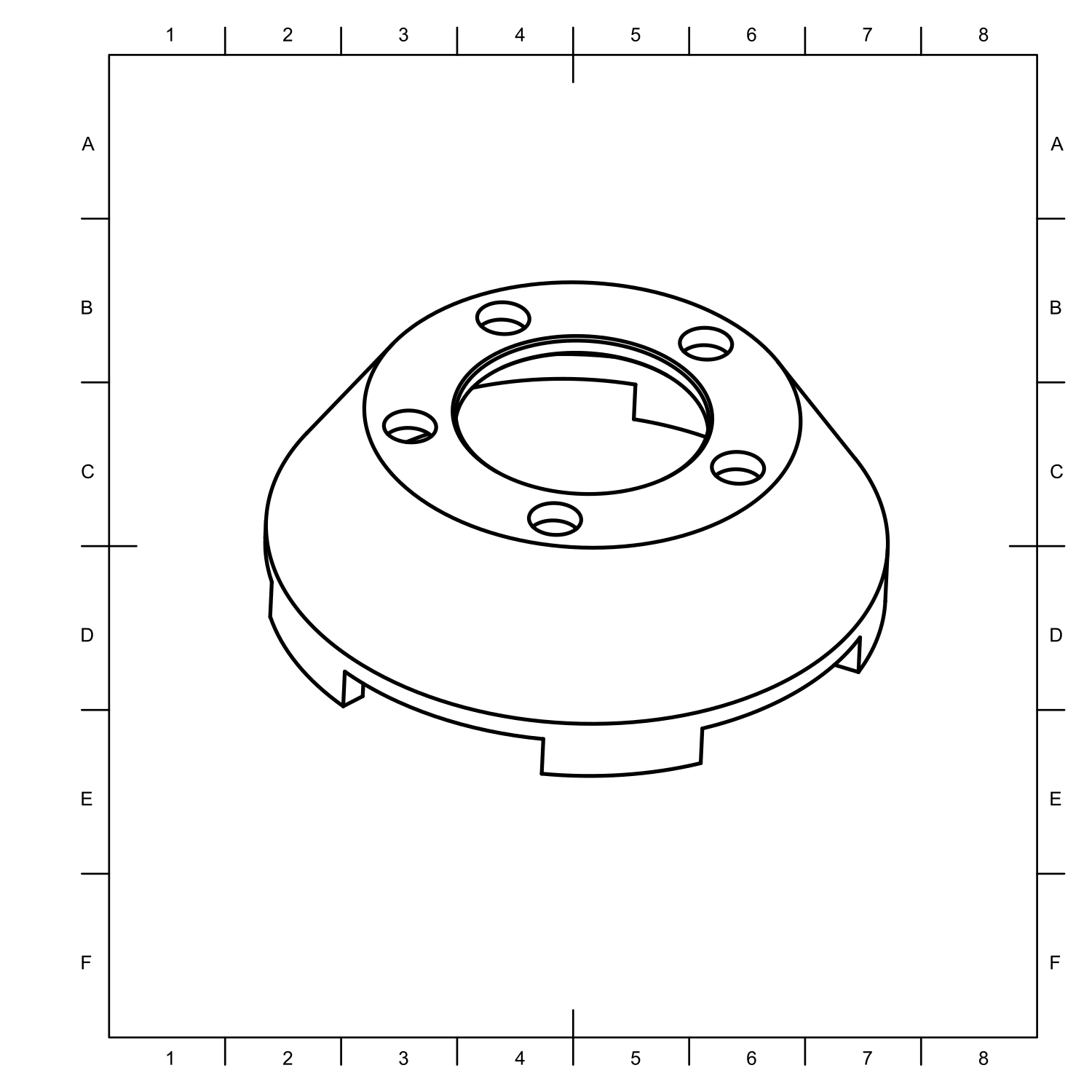

Step 1

note

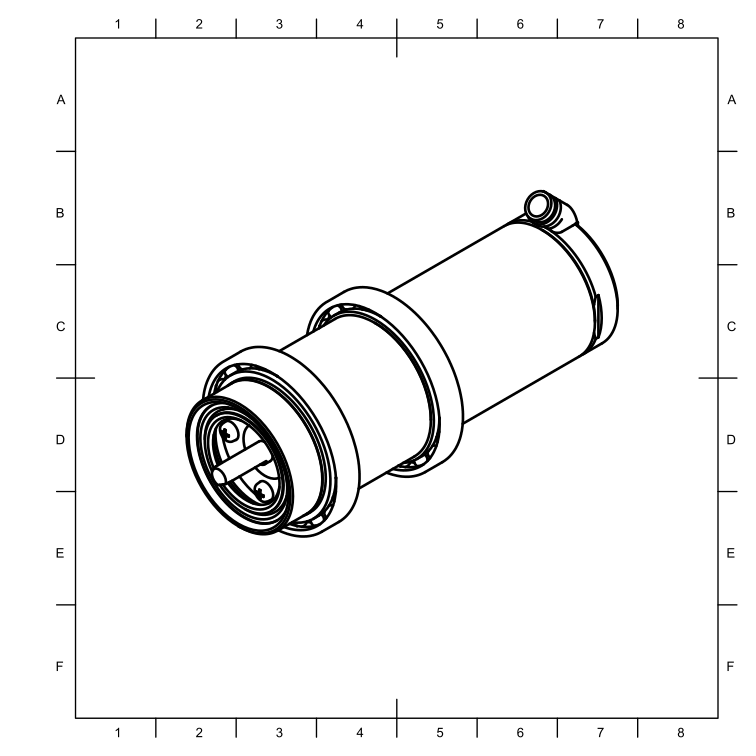

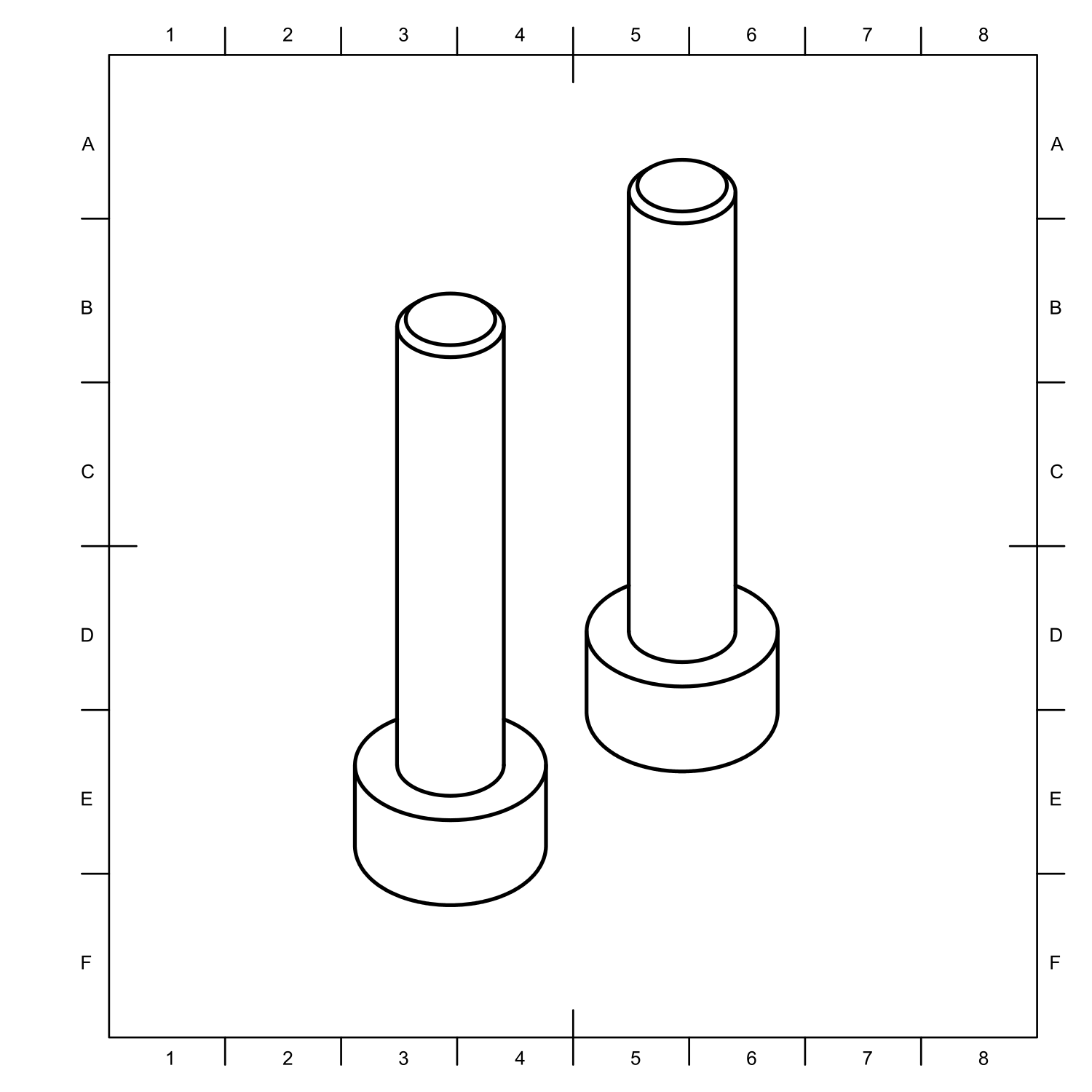

Press a decent amount of lithium grease between the shaft seal and the motor housing.

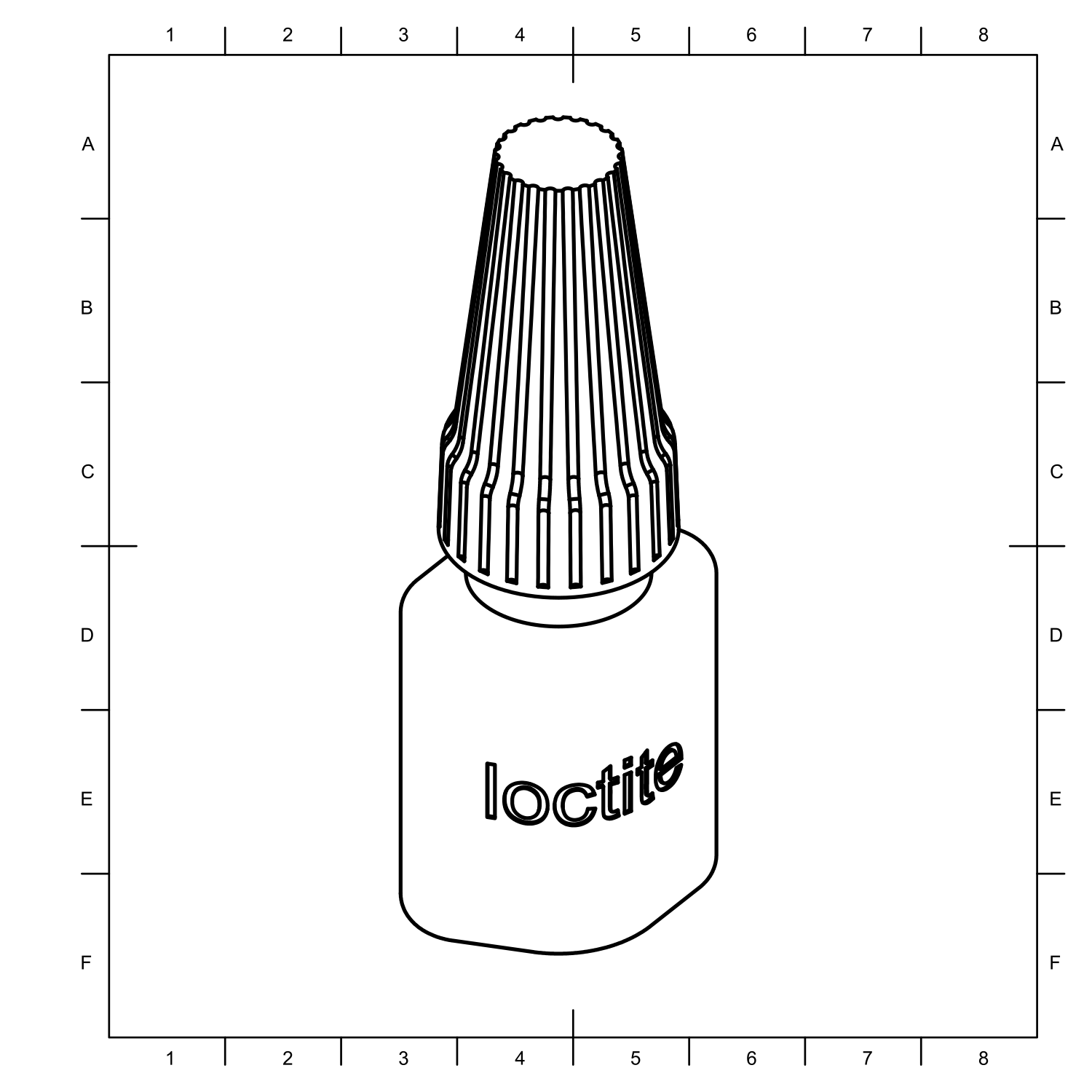

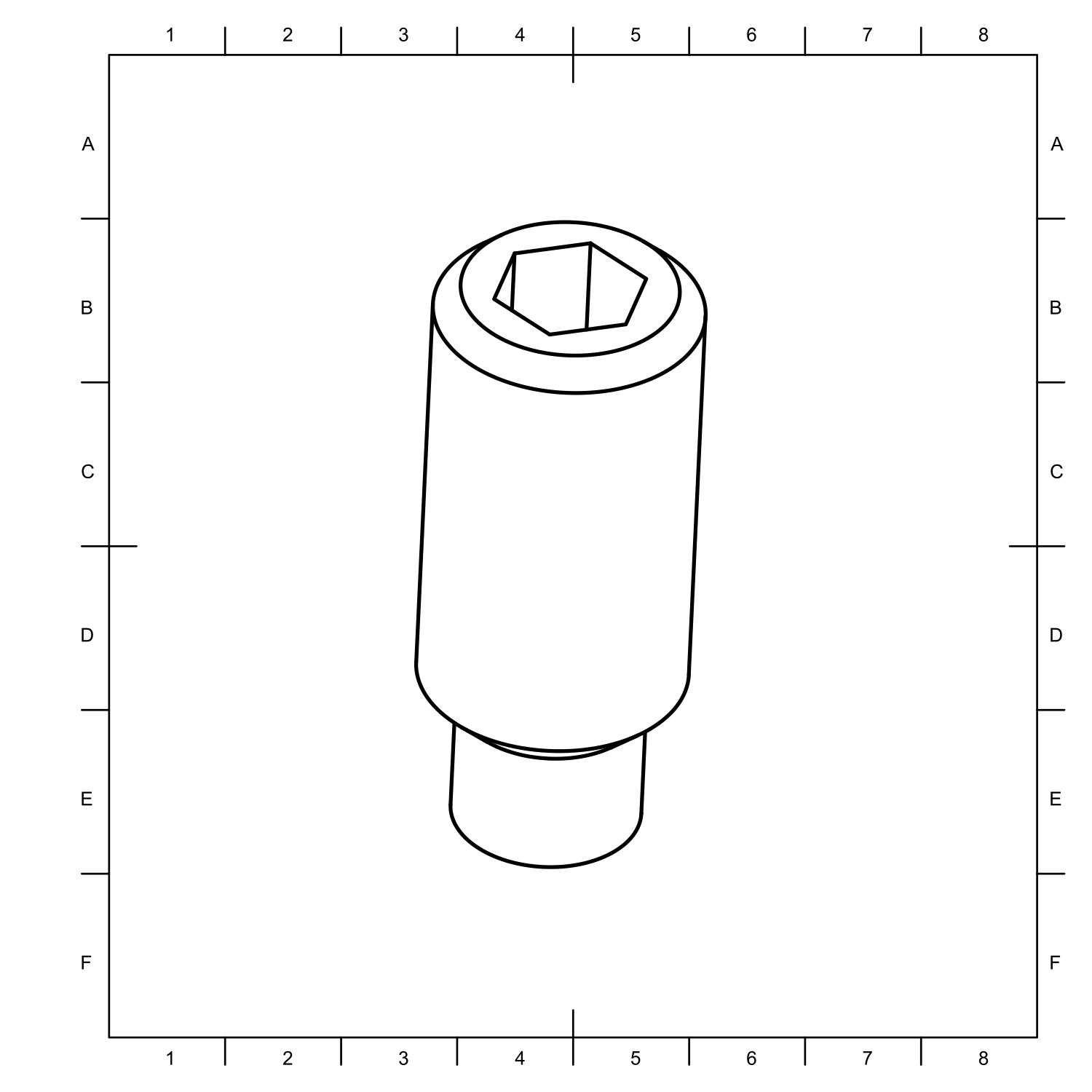

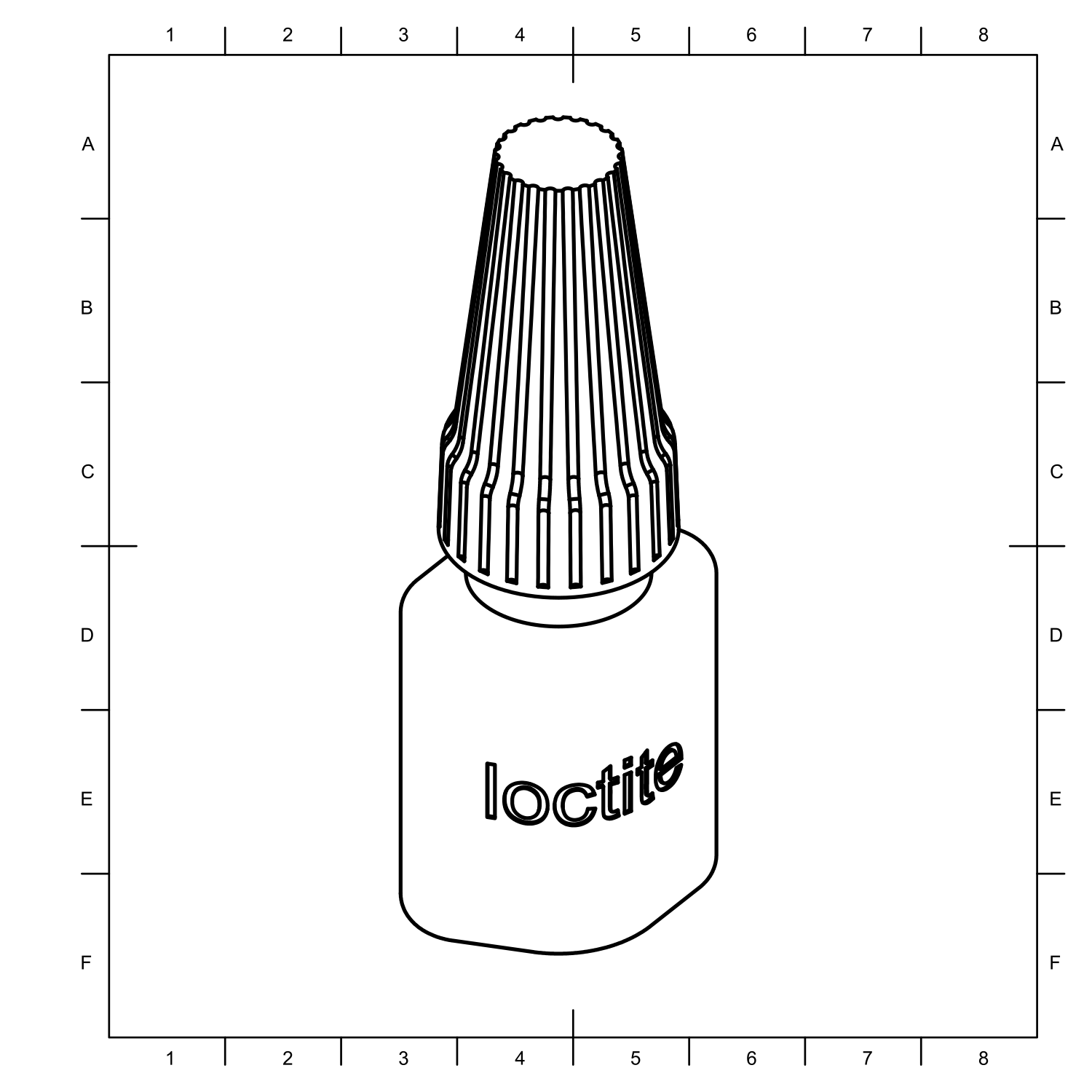

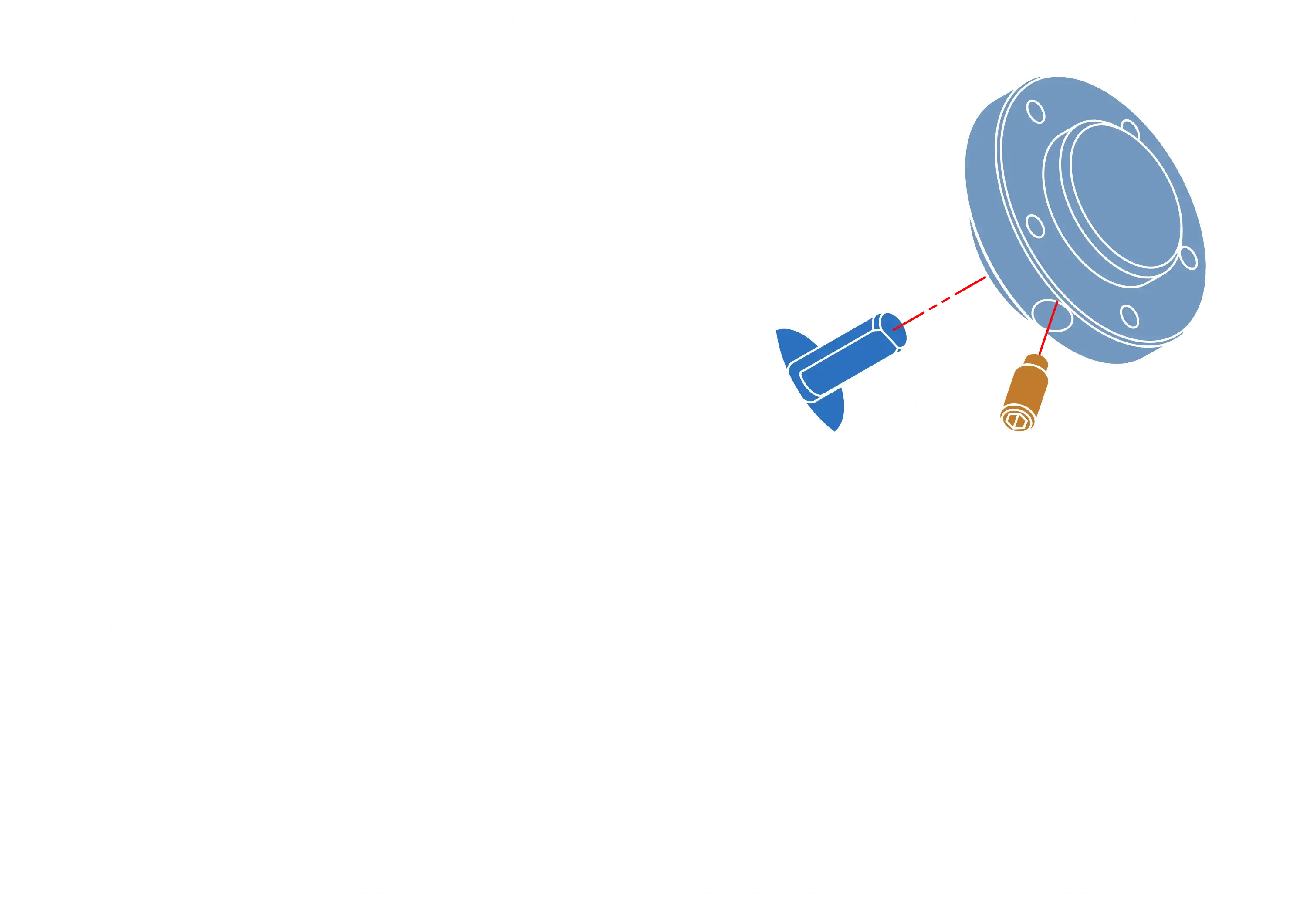

Step 2

note

Align the flat segment of motor shaft with headless screw. Use a drop of loctite to make sure it stays in place.

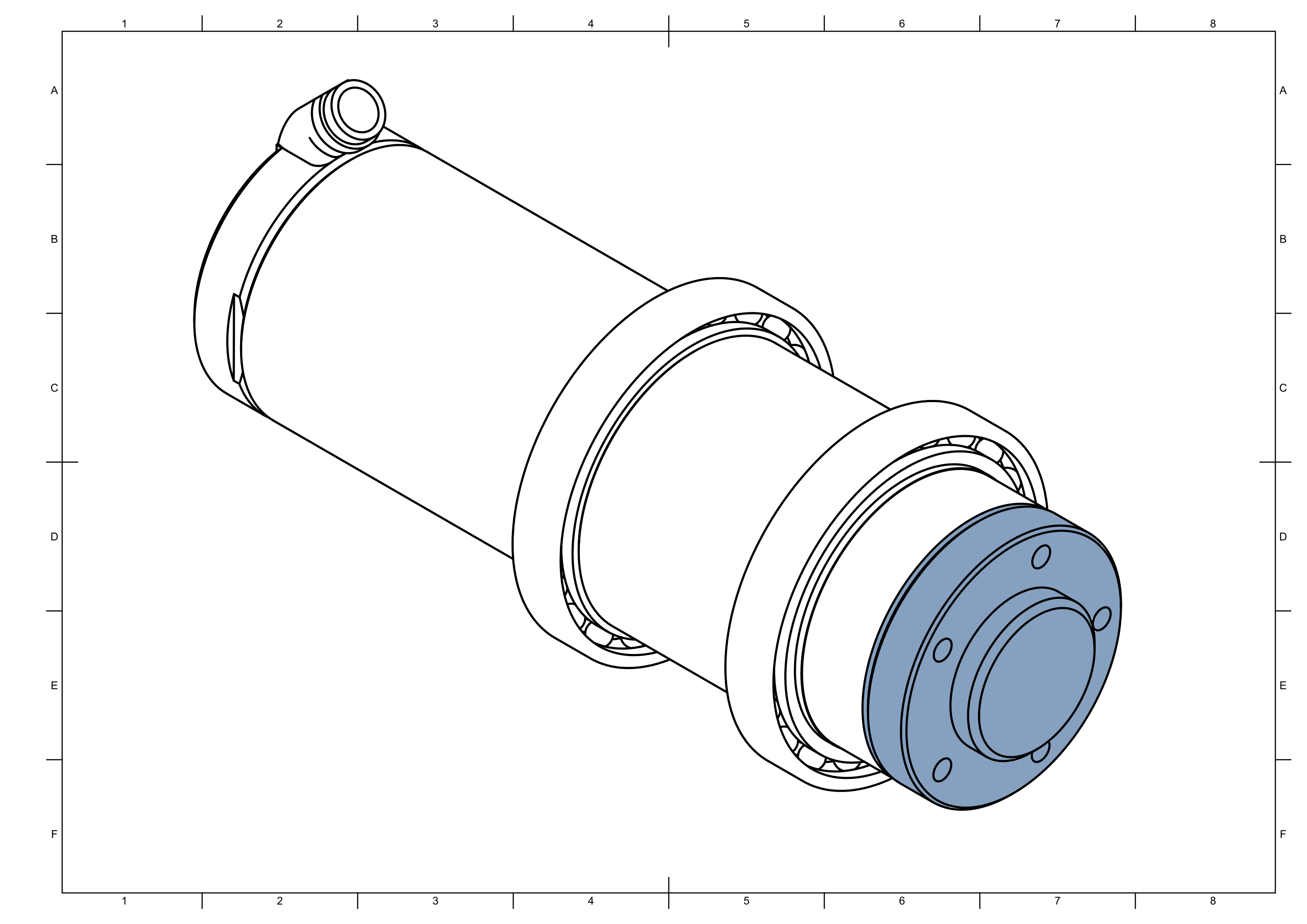

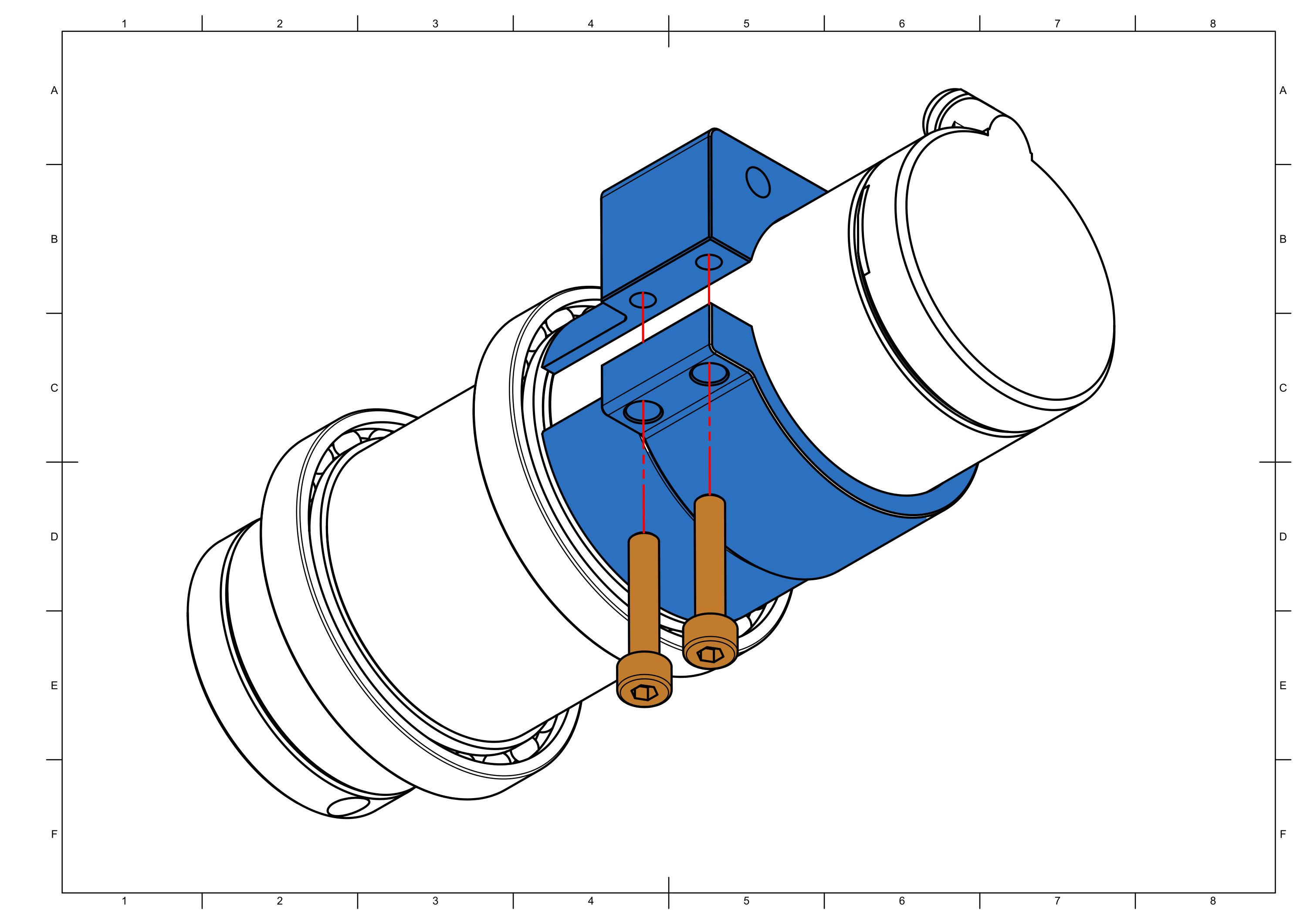

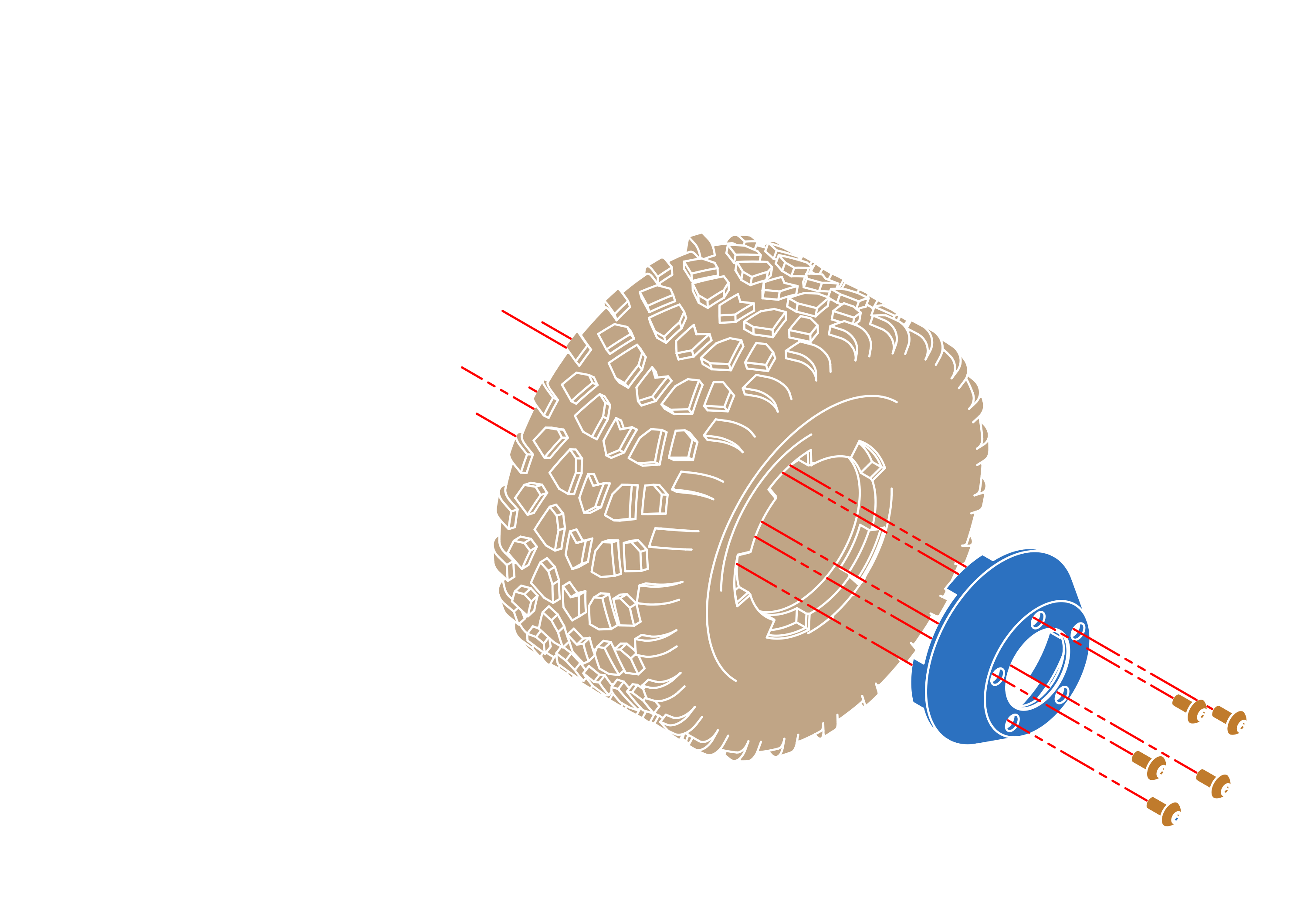

Step 3

note

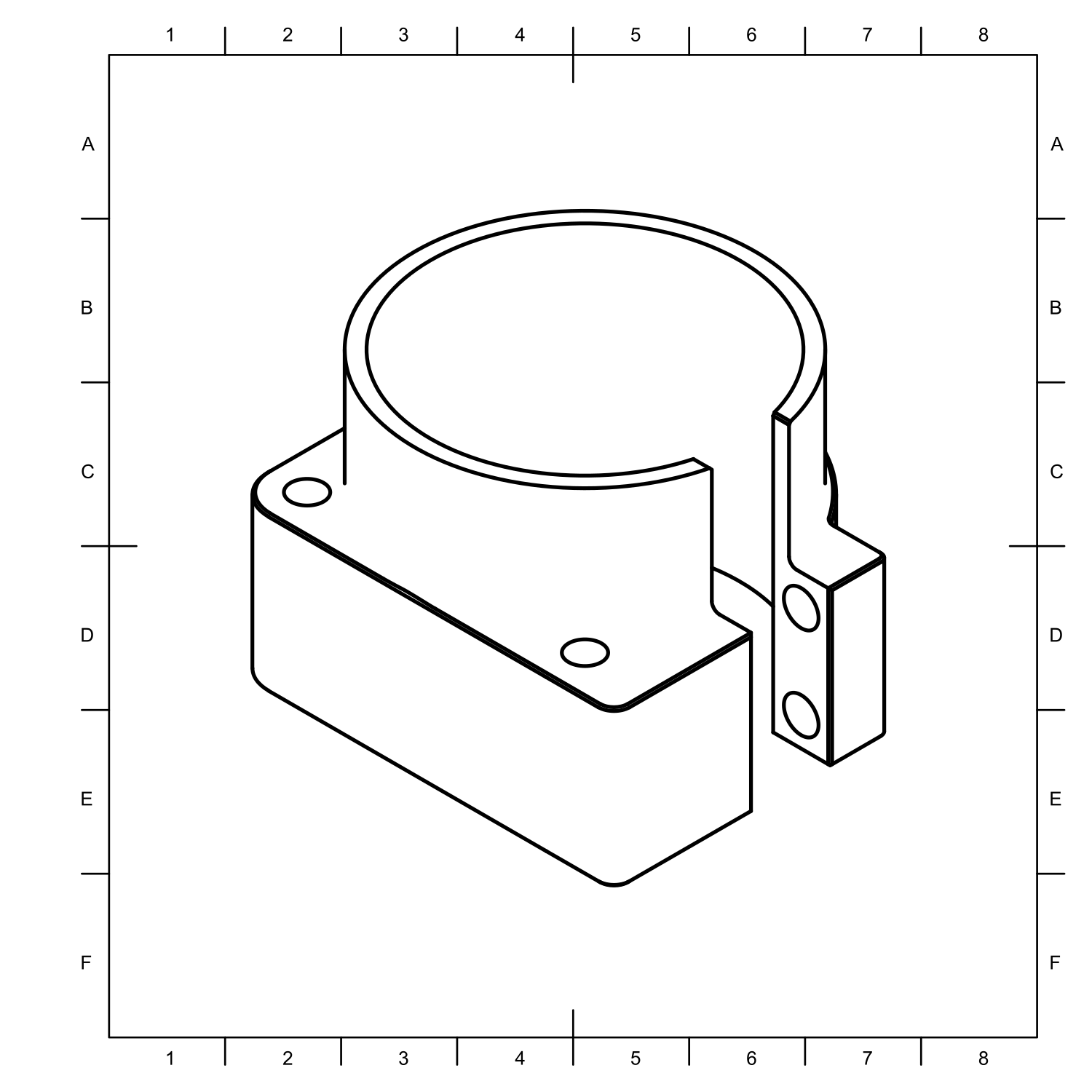

Slide the motor mount forward until it touches the base of the bearing before tightening.

Step 4

info

Repeat until you have a total of 4 wheels.